WLD-UV1313 UV FLATBED PRINTER is Industrial economic equipment which apply Skeleton triangle welding technology, nozzle collision protection, Bi-direction printing technology, "cellular" adsorption platform, water cooling system.

Can be equipped with Japan Epson 3.5 picoliter DX7, DX5 printhead

3.5PL ink drop size

1440 fine orifices

Print images comparable to photo levels

24 hours of continuous printing

Can be equipment with Ricoh GH2220 3.0 picoliter printhead

Industrial grade nozzles are low in price

3.0PL nozzle size picture is more delicate

Fast printing speed

Service life of up to 30 billion

Grayscale control gradient is more natural

Available on any material surface color pattern printing at "photo level" Image waterproof, sunscreen, abrasion resistant, non-fading, fully in line with industrial printing standards

Oman Ahmed 968 *** 9390 EPS-WLD-UV6090 11/14/2018

Oman Ahmed 968 *** 9390 EPS-WLD-UV6090 11/14/2018  Australia Martin 0416 *** 775 EPS-WLD-UV4590 09/18/2018

Australia Martin 0416 *** 775 EPS-WLD-UV4590 09/18/2018  Australia Peter 7 3*** 4652 EPS-WLD-UV2232 11/20/2018

Australia Peter 7 3*** 4652 EPS-WLD-UV2232 11/20/2018  Colombia Hernán Ro*** 322***2715 WLD-UV3040 09/25/2018

Colombia Hernán Ro*** 322***2715 WLD-UV3040 09/25/2018  India Ankur Gu*** 098***8829 WLD-UV2513 11/26/2018

India Ankur Gu*** 098***8829 WLD-UV2513 11/26/2018  HongKong Daniel W*** 852 *** 6408 WLD-UV2232 11/29/2018

HongKong Daniel W*** 852 *** 6408 WLD-UV2232 11/29/2018  Ukraine com***tion LLC 380-9***1720 WLD-UV1325 11/30/2018

Ukraine com***tion LLC 380-9***1720 WLD-UV1325 11/30/2018  USA Adam R*** '+173***0151 WLD-UV1313 12/12/2018

USA Adam R*** '+173***0151 WLD-UV1313 12/12/2018  Mongolia DUDU*** 976-***9350 WLD-UV6090 Cylinder Print 12/15/2018

Mongolia DUDU*** 976-***9350 WLD-UV6090 Cylinder Print 12/15/2018  Ecuador Mr. MARCELO M*** 593-***9195 WLD-UV4590 Cylinder Print 12/26/2018

Ecuador Mr. MARCELO M*** 593-***9195 WLD-UV4590 Cylinder Print 12/26/2018  Ecuador Mr. Romeo N*** 593-***3024 G-WLD-UV3040 12/17/2018

Ecuador Mr. Romeo N*** 593-***3024 G-WLD-UV3040 12/17/2018  Switzerland Ella M*** 41-453-***8764 WLD-UV6090 12/18/2018

Switzerland Ella M*** 41-453-***8764 WLD-UV6090 12/18/2018  Switzerland Karl Fri*** 41-5***3211 WLD-UV2513 12/18/2018

Switzerland Karl Fri*** 41-5***3211 WLD-UV2513 12/18/2018  USA Mrs. Happi N*** 1-973***5711 WLD-UV1313 12/19/2018

USA Mrs. Happi N*** 1-973***5711 WLD-UV1313 12/19/2018

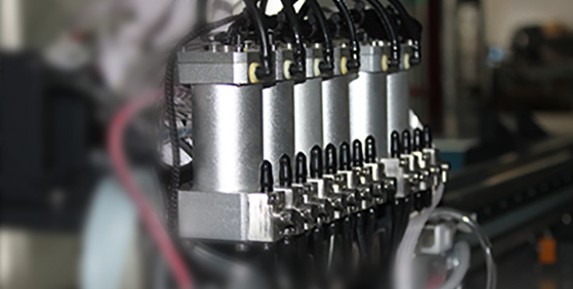

The XY axis uses a high-power AC servo motor. High torque and strong power High-speed printing does not lose weight at all. Not stuck, precise walking

Large lifting range, small head is stable, beam accuracy is 0.01

The partial block adjusts the suction area, and the air volume is adjustable to ensure the tolerance of different materials to suction. The surface of

| Model Type | WLD-UV1313 | |||

| Nozzle configuration | GH2220 industrial nozzle 1-16 Japan epson micro piezoelectric nozzle 1-2 | |||

| Maximum print size | 1300mm×1300mm/4*4' | |||

| Print speed | Ricoh gh2220:Eight nozzles | sketch model 45m2/H | production 28m2/h | High quality pattern 16m2/h |

| Epson:Two nozzles | sketch model 10m2/H | production 6m2/h | High quality pattern3m2/h | |

| Print material | Type:Acrylic, aluminum plastic board, wood, tile, foam board, metal plate, glass, cardboard and other plane objects | |||

| Thickness: 0 mm - 120 mm/0-5" | Uniform weight: 25kg | Maximum size: 1300mm x 1300mm/4*4' | ||

| Ink type | Blue, magenta, yellow, black, light blue, light red, white, light oil | |||

| The UV lamp | LED curing light, 20000 hours long use cooling water/air cooling | |||

| RIP software | PhotoPrint,Monteiro,Ultraprint;Microsoft Windows2000/XP/WIN7 | |||

| Power supply voltage,power | AC220v, hosts the largest 700w, LED - the UV lamp's largest 200-400w, 1500w vacuum adsorption platform | |||

| Image format | Tiff,JEPG,Postscript3,EPS,PDF Etc. | |||

| Color control | Comply with ICC standard, have curve and density adjustment function. | |||

| Print resolution | 720*360dpi,720*720dpi,360*1080dpi,720*1080dpi,720*1440dpi,1440*1440dpi | |||

| Operating environment | Temperature: 20 ℃ to 28 ℃ humidity: 40% to 60% | |||

| Apply the ink | Ricoh and LED-UV ink, solvent ink, textile ink | |||

| The machine size | L 1950mm X W 2410mm X H 1120mm 350KG | |||

| Packing size | L 2050mm X W 2510mm X H 1220mm 550KG | |||

High-power industrial servo motor

The XY axis uses a high-power AC servo motor.

High torque and strong power

High-speed printing does not lose weight at all.

Not stuck, precise walking and durable.

The ink supply is with negative pressure control system

Ink supply is more smooth and easy.

By using renaissance 0.01PA high precision electronic negative pressure ink supply system, the nozzle will print smoothly at a high speed wit a long time. It will maintain a relatively stable ink supply during printing.

Secondary cartridge thermostat

Secondary cartridge thermostat system enables customers in different regions

use the device to ensure color consistency and print quality

Whole frame skeletal butt welding technology

Under the factors of steel self stress,skeletal triangle butt welding technology can ensure the overall skeletal with no deformation during the transportation and in the high and low temperature.

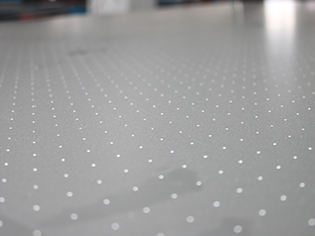

Sectional Vacuum System

This flatbed printer is designed with an adjustable air flow inside the vacuum system, based on the tolerance levels of different materials. The entire system is flat, corrosion resistant and features a uniform vacuum force.

Water cooling system

With Ricoh compressed water cooling technology, the machine has a good heat dissipation and the Led is of long service time.

Capable of handling a print area 1.3 times larger than the WLD-UV4590; the WLD-UV 1313 UV flatbed printer is equipped with a Ricoh Gh2220 or Epson Dx7 print head, and carries out printing processes with an outstanding resolution and high precision. The 1440 DPI printing machine is also able to flawlessly satisfy different industrial requirements in the usage of UV printing. With the use of the Epson print head, consistent quality of all printing applications is guaranteed.

Typical Print Materials: Acrylic, aluminum composite panels, wooden boards, ceramic tiles, foam boards, metal plates, paper

| No. | Item | Unit | Discription | Warranty | Function | Price |

| 1 | Printhead | Pcs | No | |||

| 2 | Jet board | Pcs | No | |||

| 3 | Mainboard | Pcs | No | |||

| 4 | DX7 damper with nut |

Pcs | No | |||

| 5 | DX5 damper with drawin gear |

Pcs | No | |||

| 6 | 180 Grating belt |

Pcs | No | |||

| 7 | 180 Grating reading head |

Pcs | No | |||

| 8 | Optical fiber (6M) | M | No | |||

| 9 | Printhead cable | Pcs | No | |||

| 10 | Capping | Pcs | No | |||

| 11 | 3W Ink pump | Pcs | No | |||

| 12 | 5N Electromagnet | Pcs | No | |||

| 13 | Big Doctor-bar | Pcs | No | |||

| 14 | X-axis motor | Pcs | No | |||

| 15 | Z-axis driver | Pcs | No | |||

| 16 | Red relay | Pcs | 24V | No | ||

| 17 | Common relay | Pcs | 220V | No | ||

| 18 | Power supply | Pcs | No | |||

| 19 | Belt | Pcs | No | |||

| 20 | Y-axismotor | Pcs | No | |||

| 21 | Y-axis driver | Pcs | No | |||

| 22 | Led lamp | Pcs | No | |||

| 23 | Small filter | Pcs | No | |||

| 24 | Front and back up and down the inductor | Pcs | No | |||

| 25 | Origin TP02 | Pcs | No |

Price description

For the above items, there are some consumable parts and some Non vulnerable parts, if you need the exact price, please feel free to contact our sales.

Attention

If you have bought our company printers, in order to avoid the printhead and the mainboard damage because of some wrong operation, you should install the printhead correctly in operation and maintenance according to the following way. And refer to the instructions, or under the guidance of the professional engineers operation.

1. In the process of printing appear garbled or crash phenomenon

Check whether the optical fiber is in good condition;Check whether the nozzle flat wire is in good condition;Check the mainboard DB signal to the servo drive signal for poor contact and damage phenomenon;Check whether the USB cable is well connected or is damaged, replacement of computer USB interface;Check whether the machine computer in good condition according to the standard ground.

2. The phenomenon of broken appeared in the process of printing ink

Check whether ink sac leakage cause ink flow;Check whether there is a tiny fiber materials such as adhesion in the nozzle surface;Check whether the environment temperature is too high

3. Print out the ink

Check whether the card to normal electricity, nozzle flat wire is properly connected;Check for ink ink sac;Optical fiber are in good condition

4. Water ripples to appear on the printed image

At this time should immediately stop printing, completely clean spray car guide rail and spray car bearing.If problem still, please local agent send professional skill